Check-Flex Inline valves provide dependable backflow protection for drainage manholes and pipes.

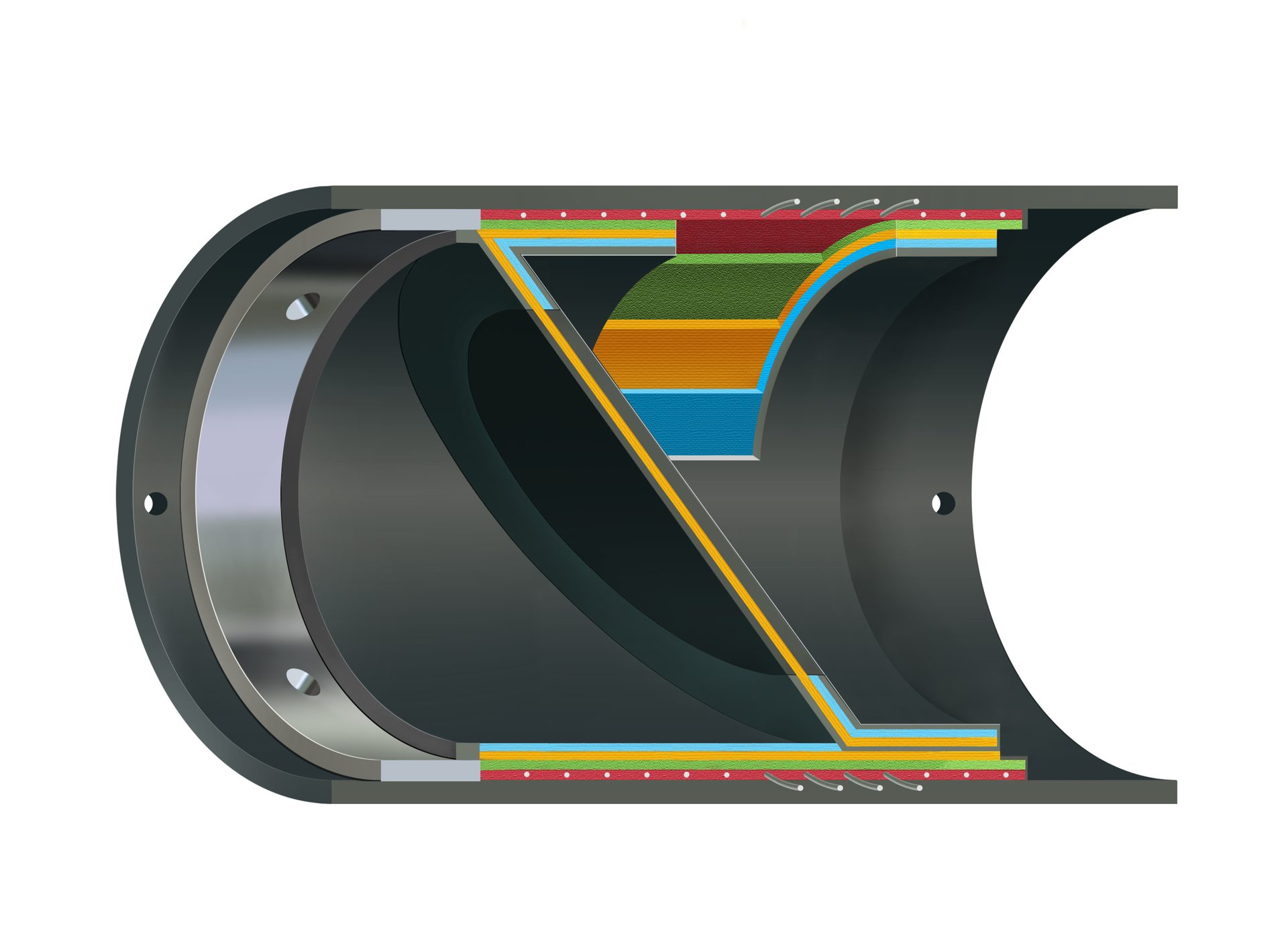

The valve body is built with cross-ply layers of rip-stop reinforced elastomer with an encased steel wire belted core.

Hello World!

How do Inline Valves work?

The inline check valve is ideal for use as a stormwater check valve and as a wastewater check valve to prevent flooding in drainage networks. The inline valve is a heavy duty, fabric ply-reinforced, vulcanized elastomer unibody product (larger sizes have integral wire reinforcement in the body as well). This makes it tough and durable, but flexible and easy to install.

Its "resting" position is closed with the saddle sealing against the body of the valve and so preventing unwanted entry into the upstream system, whether from backflow, smells, insects or rodents (such as rats). Its operation is silent and holds no risk of harm to people..

Key Features

- Low headloss maximises flow

- Quick & easy to install & to retrofit

- Fits into angled pipes

- Does not protrude

- DN100 - DN2100 standard sizes

- Slip In with C clamp or Flange

- 1 year warranty standard - 3 & 5 year available

- 25+ year design life

Inline Rubber Check Valves provide public sewer surcharge protection.

One of the many challenges encountered in urban drainage design is the cost-effective connection of development drains to the existing public sewer system.

Generally, both surface water and waste water systems drain by gravity flow, and pumped solutions are avoided where possible due to increased capital and maintenance costs. Sometimes, even though the site levels and the existing sewer gradients allow for the new drains to discharge by gravity, there is a concern regarding the impact of surcharge in the existing system on the site drainage.

Thus, measures need to be taken to reduce the risk of sewer flooding on site.

Sewer surcharge is when a sewer is overloaded beyond its design capacity and results in full pipes flowing under pressure and flooded manholes.

Unfortunately, in many older urban areas new development has meant that existing drainage networks are inadequate to the task and new sites need to take precautions when connecting to them. Surface water drainage design is most prone to this and is addressed with attenuation and flow regulators to control peak discharge. Foul or waste water drainage does not usually pose as much of a problem, except where existing sewers are combined, and thus also carry surface water.

Whether the connection is made using gravity or pumps, there needs to be a backflow prevention device, otherwise known as a non-return valve or check valve. This type of valve allows flows through, but closes to prevent waste water from flowing back up into the system when the water level rises at the connection.

During the period when the check valve is closed, the design includes for either storage of the water in the internal drainage system until it can safely drain away by gravity, or pumping at a high level into the external system (called overpumping). Once the water level in the external system has fallen, the water level in the site drainage system will push open the valve and drain the system down.

One of the many factors that can affect the proper function of a check valve in a drainage system is "ragging" due to a large volume of toilet waste and other solids being flushed into the system or litter entering through road gullies.

This is particularly an issue in systems draining public bathrooms and carparks, for example, in shopping centres and on college campuses.

Oftentimes an issue only comes to light after a flooding incident and we have been approached on a number of occasions to provide retrofit solutions. Obviously this can be a messy, and hazardous, business!

Rubber inline valves are ideal device for backflow prevention in a surcharged system draining public areas such as these.

It's unique design means that it is more than up to the challenge of these difficult environs and provides many advantages over other types of check valves. It also offers odour abatement and protection from rodents, which is always a concern with waste water drainage systems.

How to install an inline rubber valve

Benefits

- No maintenance - saving operational time and money

- 25+ years service life - long-term capital cost savings

- Reliable, proven track record - no unpleasant surprises

- Drains and self-clears in relatively flat designs - ideal for low-flows

- No areas or parts that trap or snag debris - no blockages or loss of function

Features

- Rubber construction - flexible, durable & strong

- Unibody construction with smooth surfaces and no sharp edges

- Low cracking pressure

- Located inside the pipe / ends flush with the headwall

Advantages

- Does not warp, freeze or corrode so maintains long-term function

- Easy to fit

- Low headloss

- Doesn't protrude

Related cases

We're your trusted experts!

We have decades of extensive experience with rubber check valve application in demanding Atlantic coastal sites.

Get design, CAD drawings, specification, installation and troubleshooting advice.

Get in touch

IRL 01 484 7832

UK 020 3946 3242

[email protected]

Terms, Policies and Statements

©2023 MEASURIT Technologies Ltd