Odour control an unexpected benefit

In order to mitigate flooding in Glasthule Village from sewer overflows during storm events, a CSO outfall to the sea was constructed as an interim measure. A inline rubber non-return valve was identified as the best product for installation on the CSO outfall pipe to prevent backflow from the sea entering the sewer system. The low headloss of the inline rubber valve meant that a pumped solution was not necessary.

Project details

Client

Dun Laoghaire-Rathdown County Council

Consulting Engineer

RPS

Contractor

MJS Civil Engineering

Design Details

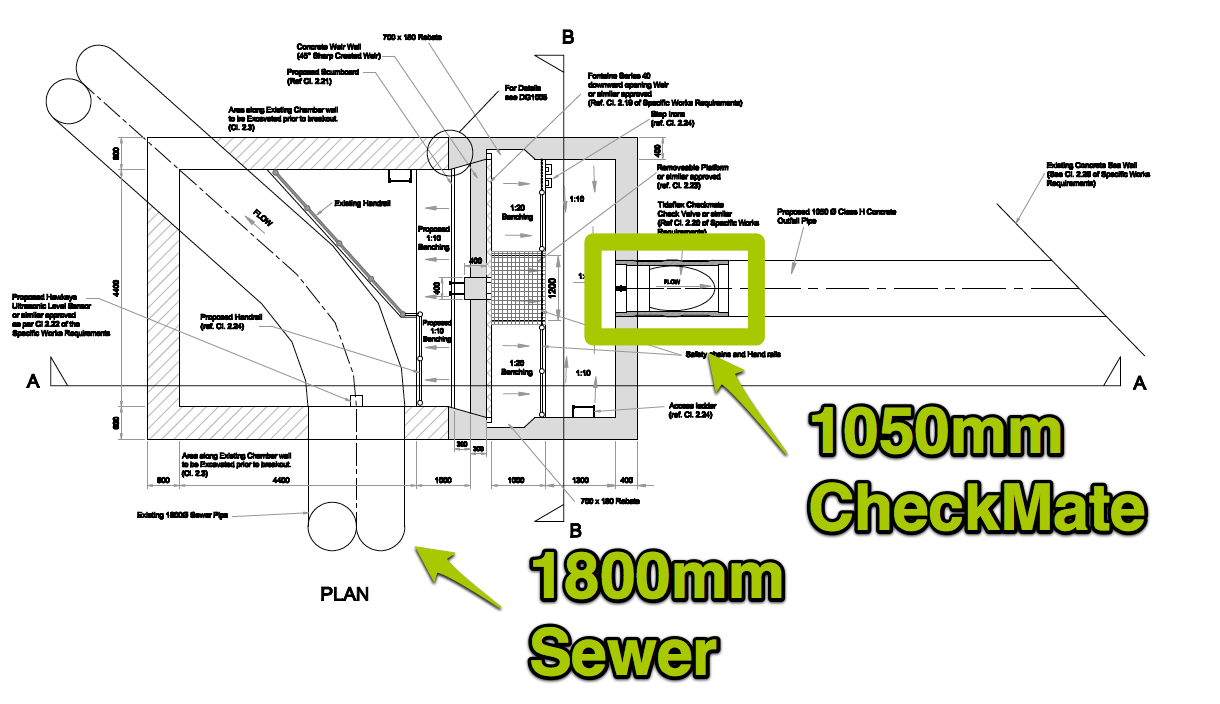

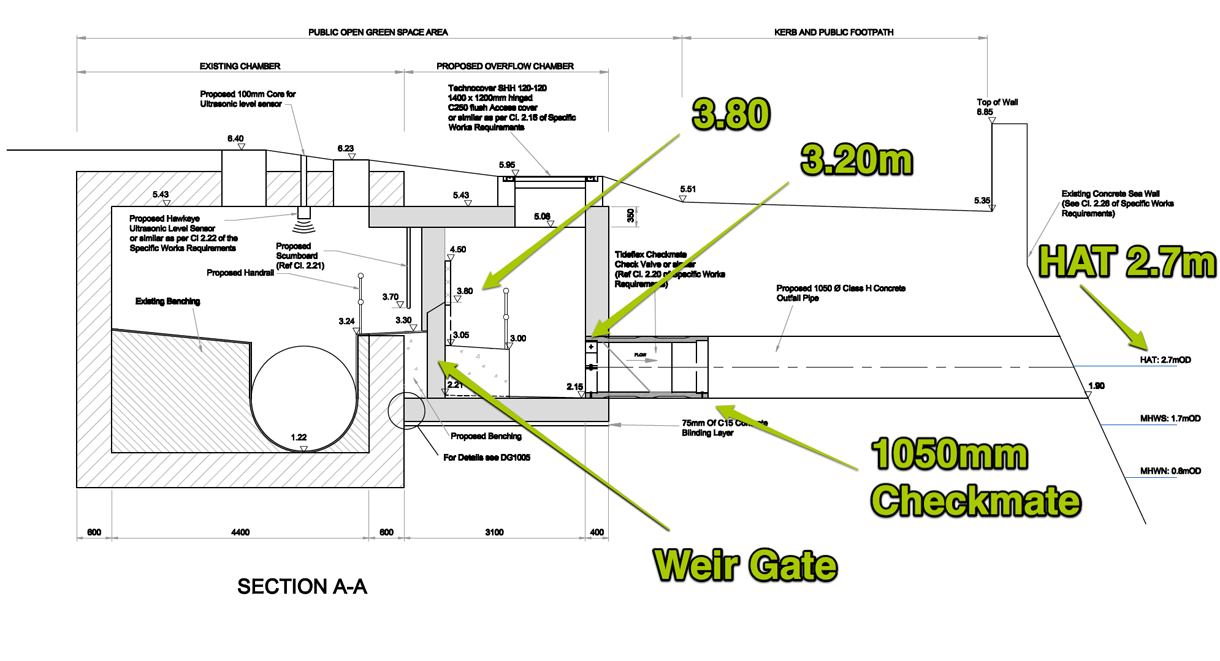

1050mm CheckMate valve with max. headloss 450mm at 4m3/s flow

Glasthule Village in Dun Laoghaire, Dublin was identified as being at risk from flooding during severe storm events and the interim measure adopted was an overflow structure on the large combined sewer system. This work was conducted on behalf of the Dun Laoghaire-Rathdown County Council (DLRCC) and completed in 2011.

The project involved the provision of a high level emergency overflow connecting an existing access manhole on the sewer tunnel to West Pier Pumping Station to the existing sea wall adjacent to the former Dun Laoghaire Baths site. The overflow system included an adjustable weir, a depth monitor linked to the DLRCC telemetry system, a non-return valve and associated pipework.

The non-return valve chosen was a rubber inline valve from Measurit. The low headloss of this valve meant that a pumped solution was not needed. A 1050mm inline rubber valve was manufactured and installed in 2010 and has been in operation with no issues since then. The Inline Rubber valve was lifted into place and inserted into the 1050mm overflow pipe and fixed in place using existing equipment on site - no specialist equipment or staff necessary.

Plan of New Overflow Chamber

Section of New Overflow Arrangement

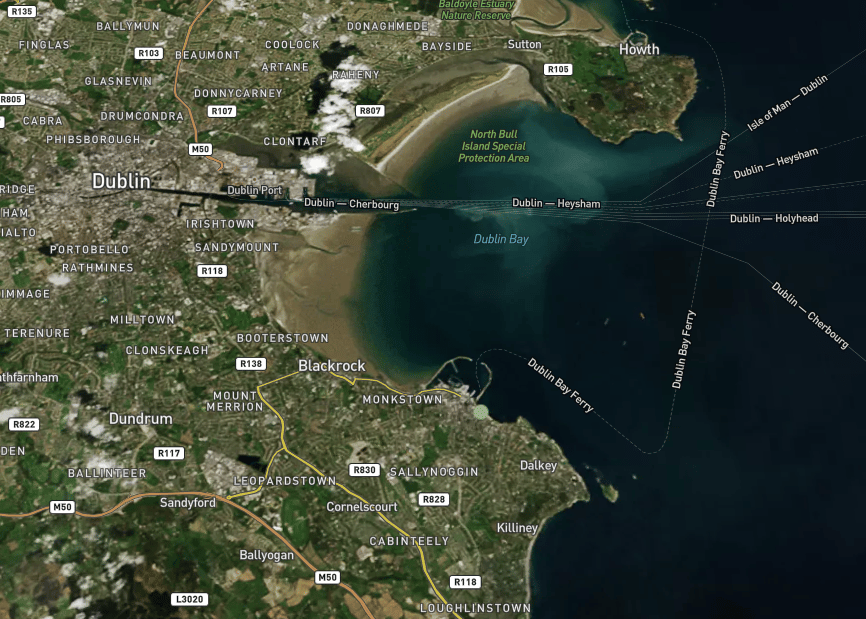

Outfall Location

Simple sealing to pipe of rubber inline valve

The inline rubber check valve is very easy to install by simply inserting inside the end of the pipe from the upstream or downstream end and clamping in place, offering a versatile solution, giving the option for installing at many different locations i.e. chamber inlet or chamber outlet or at the end of an outfall, no modification is required to the structure or pipework.

The inline valve is simply clamped in place via internal expanding clamp, place the clamp in the end you are fitting from, insert into pipe and expand the clamp using a spanner and pin in place.

Unloading 1050mm inline valve

1050mm Outfall pipe to Sea.

Lowering inline rubber valve into Chamber.

Guiding the valve into position.

Inserting into pipe.

Final Push!

Time for fixing expanding clamps!

Mission Complete!

Topping off.

Inline rubber check valves offer Minimal headloss and High Backpressure rating

We're your trusted experts!

We have decades of extensive experience with rubber check valve application in demanding Atlantic coastal sites.

Get design, CAD drawings, specification, installation and troubleshooting advice.

Get in touch

IRL 01 484 7832

UK 020 3946 3242

[email protected]

Terms, Policies and Statements

©2023 MEASURIT Technologies Ltd